| Shaft Coupler | Gears | Sprockets |

|

|

|

Regardless of your drive source ( motor, stepper, human, wind...) the first consideration that you must consider is how you will connect your drive source to your mechanism. Most small motors will just have a plain shaft, some of these will be keyed with a flat side. Depending on your mechanism, you may chose a shaft coupler, a pinion gear, or a sprocket to connect to your drive shaft. Most of these couplers can be found with a set screw, which can be tightened down on to the shaft to secure the part.

| Gears | Sprocket & Chain | Belt and Pulley |

|

|

|

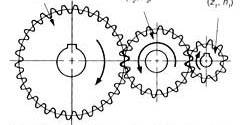

There are many considerations when selecting different drive systems. Gears can be a pretty simple way of connecting small motors in to a system. Sprockets and Chains provide a more robust drive system for larger, heavier parts, or for parts that are separated by a distance that makes gears impractical. Belts and Pulleys are similar to sprockets and chains, but in the case of a v-belt, there are no teeth to prevent the belt from slipping. On a small scale, you can find toothed belts and sprockets that do not allow slippage and assure a constant drive transmission. Here is a link to a gear generator that can generate templates for gears to be cut in any material.

Friction is always a consideration in a mechanical system. Friction will wear out parts, and can damage motors and electronics if not managed well. The most common source of friction is on rotating shafts, between the shaft and housing. You can reduce friction by using a bushing or a bearing where your shaft contacts the static housing. As a general rule, with bushings you want to combine a softer material with a hard material, i.e. a steel shaft and a bronze bushing, or a steel shaft and a nylon bushing.

Bushings and Bearings have unique adventages and specific applications that work for different needs. Bushings can be very good for limited rotational applications, like a hinge that slowly opens back and forth. Bearings are usually preferred if you are looking at constant, high-speed rotation.

| Bushing | Bearings | Mounted Bearing |

|

|

|

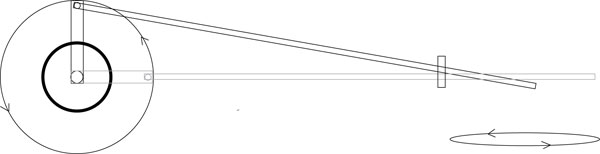

Cams and Levers can be used in many different ways to translate rotational motion in to linear motion.

When determining what type of motor you need, speed and torque are the things you need to consider to help make your decision. If you are looking for a slow movement, you will have to combine a motor and gear or pulley system to slow the motor down. You can make this yourself, but it might be easier to find a gear motor that matches your needs already. Gear motors are motors that have a gear housing built in to the motor housing and allow various output speeds, i.e. 300 RPM, 24 RPM, 1 RPM...... Most gear motors do make a bit of noise, but if you find a precision-made version they can be silent.

Speed is measured in RPM or Revolutions Per Minute: how many revolutions the shaft turns in one minute....

Torque is measured in pound-inches ( lbin ) or gram-centimeters ( gmcm ) or Newton-centimeters ( Ncm ). Torque is found by multiplying a force times the length of the lever arm. A torque rating of .88 lbin means that the motor can handle a .88 lb force applied to a one inch lever arm. If your lever arm was half this length, 0.5 in, then the motor would be able to produce 1.66 lb of force, which still satisfies our equation for torque rating.

Torque= Force (lbs or gms or N) x Lever Arm ( in or cm)

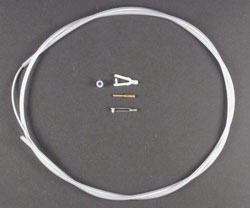

RC hobby stores are a great source for miniature, precision-made parts that are great for mechanical work. Two things that I've used a lot are Ball Links and Flex Cables. Ball links are linkage points that can thread on the end of a rod, or be connected to a flex cable. Ball links allow continuous rotation and dual axis pivot. Most of the ball links you find in hobby stores are plastic and brass, which is fine for back and forth movement, but not for high speed or constant rotation. If you need a linkage for high speed or continuous rotation you have to find more robust linkages that have steel housing and bronze or ball bearing core. These linkages are sometimes called Rod Ends and can be found at Clippard and McMaster Carr.

Flex Cables are a flexible braided steel cable inside a plastic sleeve, and they allow rotational and linear motion to be transferred around bends or in loops. The cables that you see on bicycle brakes, which connect the hand levers to the brakes, are examples of flex cables.

| Dubro Ball Links | Dubro Flex Cable | Clippard Rod End |

|

|

|

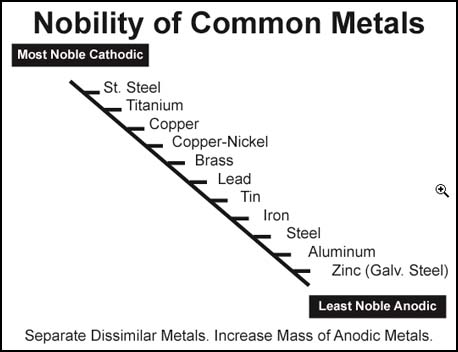

When you start to construct a mechanical system, the materials are of obvious importance, but something that is often overlooked is material compatibility. Certain metals are not compatible and will corrode each other due to galvanic corrosion of components. The Nobility chart is a good reference to consult if you are curious about two metals being compatible.

This nobility chart lists some of the more common metals used in architecture. The higher the metal is ranked on the chart the more noble or cathodic it is. This means its potential for galvanic corrosion is low. The lower the metal is ranked on the chart the less noble or more anodic it is. Its potential for attack by galvanic corrosion is much greater. For example you may use copper with lead because they are ranked close on the chart. The further the spread from copper, coming down the chart, the more serious the situation is, and the greater the risk of galvanic corrosion. In a copper-aluminum couple, for example, the aluminum will be rapidly attacked under galvanic corrosion conditions.

Video on gears: Hila Science and Clocks: Hila Science 2